Mechanical Estimating Services: The Key to Accurate Project Costing

Accurate cost estimation is the backbone of any successful construction project, especially when it comes to mechanical systems. From HVAC and plumbing to industrial piping and fire protection, mechanical estimating services help contractors, engineers, and project managers forecast project costs with precision.

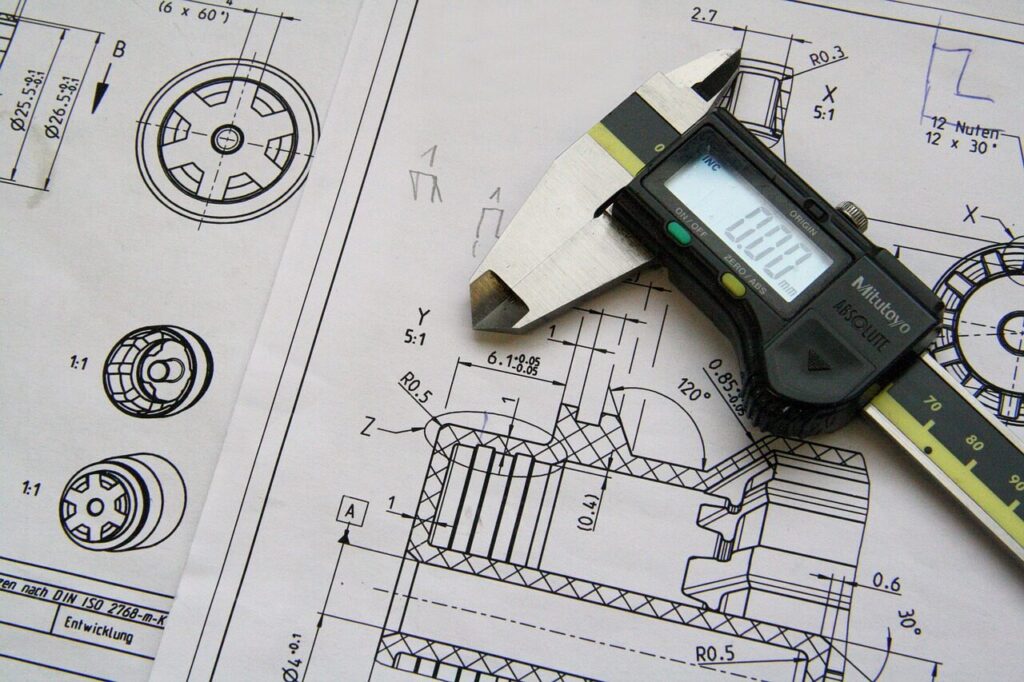

Mechanical estimating involves analyzing blueprints, quantifying materials, calculating labor costs, and considering overhead expenses to provide a reliable cost projection. Without a detailed estimate, projects risk unexpected expenses, delays, and budget overruns.

In this guide, we will explore the fundamentals of mechanical estimating services, their significance, the industries that rely on them, and how professional estimating can streamline project execution.

What Are Mechanical Estimating Services?

Mechanical estimating services involve calculating the cost of mechanical components in a construction project. These components include heating, ventilation, and air conditioning (HVAC) systems, plumbing networks, industrial piping, and mechanical equipment installations.

The process requires in-depth knowledge of mechanical systems, industry pricing trends, and labor costs. Estimators analyze architectural and mechanical drawings, assess material requirements, and compile cost reports that contractors use for bidding and budgeting.

Mechanical estimating services are critical for ensuring financial feasibility, reducing waste, and improving project efficiency. By providing detailed cost breakdowns, these services help contractors make informed decisions and submit competitive bids.

Industries That Rely on Mechanical Estimating Services

Mechanical estimating services play a crucial role in various industries where mechanical systems are an integral part of infrastructure and operations.

1. Construction and Real Estate

In commercial, residential, and industrial construction, mechanical estimators help determine the costs of HVAC installations, plumbing systems, and fire protection solutions. Their insights ensure cost-effective designs and efficient installations.

2. Industrial and Manufacturing Facilities

Factories, power plants, and refineries require extensive mechanical systems for operations. Mechanical estimators assess costs for piping networks, ventilation, and process equipment, helping businesses optimize budgets and prevent cost overruns.

3. Oil & Gas Sector

Pipeline construction, refineries, and offshore facilities rely on precise mechanical cost estimation. Estimators calculate the costs of materials, labor, and specialized equipment required for mechanical infrastructure.

4. Healthcare and Pharmaceuticals

Hospitals, laboratories, and pharmaceutical production units require complex mechanical systems, including sterilization equipment, clean air ventilation, and medical gas piping. Accurate estimates are essential for budgeting and compliance with health regulations.

5. Commercial and Institutional Buildings

Retail centers, educational institutions, and government buildings depend on efficient HVAC, plumbing, and fire suppression systems. Mechanical estimating ensures optimal resource allocation and cost control.

By providing accurate cost projections, mechanical estimating services support efficient planning and execution across these industries.

Key Components of Mechanical Estimating

Mechanical estimating involves multiple elements that contribute to an accurate cost forecast.

Material Takeoff and Quantity Estimation

Estimators analyze project blueprints to determine the quantity of pipes, valves, ductwork, and insulation materials required. A detailed quantity takeoff helps avoid shortages and ensures precise procurement.

Labor Cost Estimation

Labor expenses depend on the project’s complexity, workforce availability, and regional wage rates. Estimators calculate labor costs based on industry standards, ensuring accurate budget allocations.

Equipment and Machinery Costs

Mechanical installations often require heavy equipment such as chillers, boilers, and compressors. Estimators assess whether purchasing or renting machinery is the most cost-effective approach.

Subcontractor and Specialty Trade Costs

In complex projects, specialized subcontractors handle tasks like welding, system testing, and commissioning. Mechanical estimators evaluate subcontractor pricing to integrate into the overall budget.

Overhead and Profit Margins

Indirect costs such as insurance, project management, and administrative expenses are factored into the estimate. Additionally, estimators apply profit margins to ensure financial feasibility.

Each of these components contributes to a well-rounded cost estimate, enabling contractors to prepare realistic bids and execute projects efficiently.

The Mechanical Estimating Process

Mechanical estimating follows a structured approach to ensure accuracy and consistency.

1. Reviewing Project Specifications

The estimator begins by analyzing project plans, engineering drawings, and technical documents to understand the scope and complexity of the mechanical systems involved.

2. Conducting a Detailed Quantity Takeoff

Using specialized software, estimators calculate the exact materials required for HVAC systems, piping, plumbing, and mechanical equipment installations. This step ensures resource optimization and cost accuracy.

3. Determining Labor and Equipment Costs

Estimators assess labor requirements, workforce availability, and wage rates. They also factor in machinery costs, whether through direct purchase or rental.

4. Applying Unit Costs and Pricing Strategies

Industry-standard unit costs for materials, labor, and subcontractors are applied. The estimator also considers price fluctuations and supplier quotes to ensure an up-to-date estimate.

5. Compiling and Reviewing the Estimate

A final review ensures all cost factors are accounted for. The estimate is then compiled into a detailed cost report for client approval and bidding purposes.

This structured process ensures mechanical estimates are accurate, competitive, and aligned with industry standards.

Benefits of Professional Mechanical Estimating Services

Outsourcing mechanical estimating services provides numerous advantages for contractors, project managers, and developers.

1. Enhanced Accuracy and Risk Reduction

Professional estimators leverage expertise and technology to deliver highly accurate cost estimates, reducing the risk of cost overruns and financial losses.

2. Time and Resource Efficiency

Manual estimation is time-consuming and prone to errors. Mechanical estimating firms use advanced software to generate fast, precise calculations, allowing contractors to focus on project execution.

3. Competitive Bidding Advantage

Detailed and well-structured estimates improve bid quality, increasing the chances of winning contracts while ensuring profitability.

4. Cost Optimization and Budget Control

By identifying cost-saving opportunities in material procurement and labor allocation, estimators help clients maximize efficiency and stay within budget.

5. Access to Industry Expertise

Experienced mechanical estimators have in-depth knowledge of industry trends, pricing fluctuations, and compliance requirements, providing valuable insights for project planning.

With these benefits, professional mechanical estimating services contribute to streamlined project execution and financial stability.

Software and Tools for Mechanical Estimating

Modern estimating software enhances accuracy and efficiency in mechanical cost estimation. Some widely used tools include:

- Trimble AutoBid Mechanical: Specializes in HVAC and plumbing cost estimation.

- FastPIPE, FastDUCT, and FastWRAP: Designed for piping and ductwork takeoff.

- PlanSwift & Bluebeam Revu: Provides general construction estimating and quantity takeoff capabilities.

QuoteSoft Piping: Offers detailed pipe estimation solutions.

These tools streamline the estimating process, reduce human error, and improve project planning accuracy.

Challenges in Mechanical Estimating and How to Overcome Them

Fluctuating Material Prices

Price variations in metals, pipes, and HVAC components can impact estimates. Regular updates to pricing databases and supplier quotes help maintain accuracy.

Labor Cost Uncertainty

Workforce availability and wage fluctuations affect project costs. Estimators consider regional trends and adjust estimates accordingly.

Project Scope Changes

Modifications in project requirements can lead to cost variations. Clear communication and real-time estimate adjustments help mitigate this challenge.

By addressing these issues proactively, mechanical estimators can ensure reliable cost projections.

FAQs

How do mechanical estimators ensure accurate cost estimates?

Estimators use industry data, supplier quotes, and advanced estimating software to provide precise cost calculations.

What factors influence mechanical estimation costs?

Material prices, labor rates, project complexity, and equipment costs all play a role in determining the final estimate.

Can outsourcing mechanical estimating improve project efficiency?

Yes, outsourcing saves time, reduces overhead costs, and provides access to expert estimators who deliver accurate and timely estimates.

How does mechanical estimating help in bidding?

A detailed estimate strengthens bid proposals, making them competitive while ensuring profitability.

Conclusion

Mechanical estimating services are essential for accurate budgeting, resource planning, and cost control in construction projects. By leveraging expert estimators and modern software, contractors can improve bidding success, optimize costs, and enhance project efficiency.

Whether you are a contractor or a project manager, investing in professional mechanical estimating services ensures financial stability and operational success.